-

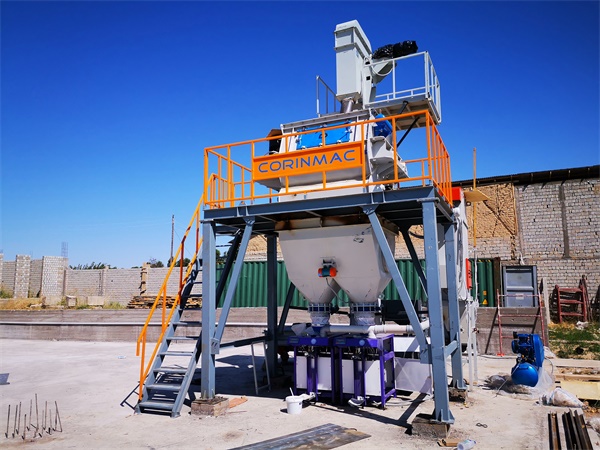

Speciális habarcsgyártó sor a kazahsztáni építőipar számára

Idő:2022. július 5.

Elhelyezkedés:Shymkent, Kazahsztán.

Esemény:A felhasználó rendelkezésére bocsátottunk egy 10TPH gyártási kapacitású száraz porhabarcs gyártósort, beleértve a homokszárító és -szűrő berendezéseket.

A kazahsztáni szárazhabarcs-piac növekszik, különösen a lakó- és kereskedelmi építőiparban.Mivel Shymkent a Shymkent régió fővárosa, ez a város fontos szerepet játszhat a régió építőipari és építőanyag-piacán.

Ezenkívül a kazah kormány számos intézkedést hozott az építőipar fejlesztése érdekében, például infrastrukturális projektek végrehajtása, lakásépítés támogatása, külföldi befektetések vonzása és egyebek.Ezek a politikák ösztönözhetik a szárazhabarcs-piac keresletét és fejlődését.

Cégünk célja mindig is az volt, hogy ésszerű megoldásokat tervezzünk a felhasználók számára, segítsünk ügyfeleinknek hatékony és jó minőségű habarcs gyártósorok létrehozásában, és lehetővé tegyük az ügyfelek számára a gyártási követelmények mielőbbi teljesítését.

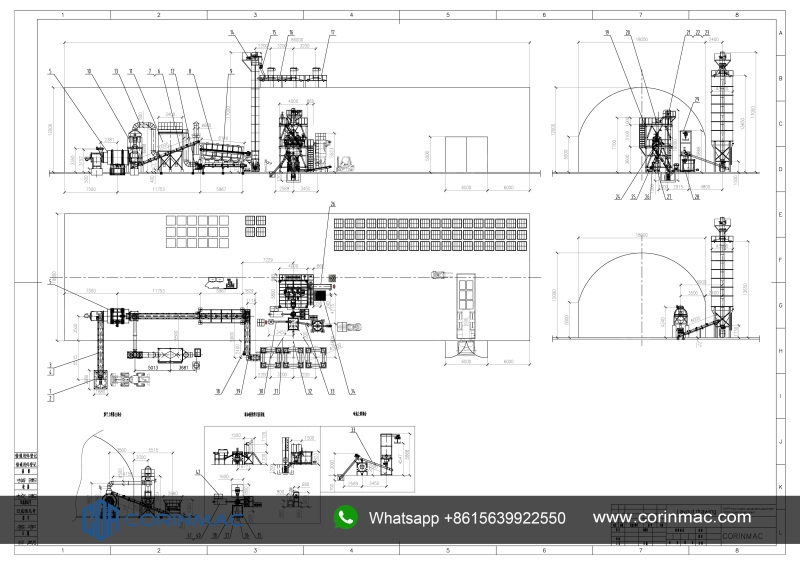

2022 júliusában az ügyféllel folytatott többszöri kommunikáció révén végül véglegesítettük a 10TPH speciális habarcs gyártósor tervét.A felhasználó munkaházának megfelelően a terv elrendezése a következő:

Ez a projekt egy szabványos szárazhabarcs gyártósor, beleértve a nyers homok szárító rendszert.A felhasználói igényeknek megfelelően a simítószita a homok száradás utáni szitálására szolgál.

A nyersanyag-adagolási rész két részből áll: a fő összetevők adagolásából és az adalékos adagolásból, és a mérési pontosság elérheti a 0,5% -ot.A keverő az újonnan kifejlesztett egytengelyes eke-keverőnket alkalmazza, amely gyors fordulatszámmal rendelkezik, és csak 2-3 percet igényel minden adag keveréshez.A csomagológép a levegős flotációs csomagológépet alkalmazza, amely környezetbarátabb és hatékonyabb.

Most az egész gyártósor az üzembe helyezés és az üzemeltetés szakaszába lépett, és barátunk nagyon bízik a berendezésben, ami természetesen így van, mert ez egy olyan kiforrott gyártósor, amelyet sok felhasználó ellenőriz, és azonnal elhozza. gazdag előnyökkel jár barátunknak.

-

Az úttörő vásárló a 3D betonhabarcsos nyomtatási technológiát alkalmazza

Idő:2022. február 18.

Elhelyezkedés:Curacao.

Berendezés állapota:5TPH 3D nyomtató betonhabarcs gyártósor.

Jelenleg a betonhabarcsos 3D nyomtatási technológia nagy előrehaladást ért el, és széles körben alkalmazzák az építőiparban és az infrastruktúra-iparban.A technológia lehetővé teszi olyan összetett formák és szerkezetek létrehozását, amelyek a hagyományos betonöntési módszerekkel nehezen vagy egyáltalán nem érhetők el.A 3D nyomtatás olyan előnyöket is kínál, mint a gyorsabb gyártás, a kevesebb hulladék és a nagyobb hatékonyság.

A 3D nyomtatáshoz használt száraz betonhabarcsok piacát a világon a fenntartható és innovatív építési megoldások iránti növekvő kereslet, valamint a 3D nyomtatási technológia fejlődése vezérli.A technológiát számos építőipari alkalmazásban alkalmazták, az építészeti modellektől a teljes méretű épületekig, és forradalmasíthatja az iparágat.

Ennek a technológiának a kilátásai is nagyon szélesek, és a jövőben várhatóan az építőipar fősodrává válik.Eddig sok felhasználó tette meg a lábát ezen a területen, és kezdtük el a betonhabarcsos 3D nyomtatási technológia gyakorlati alkalmazását.

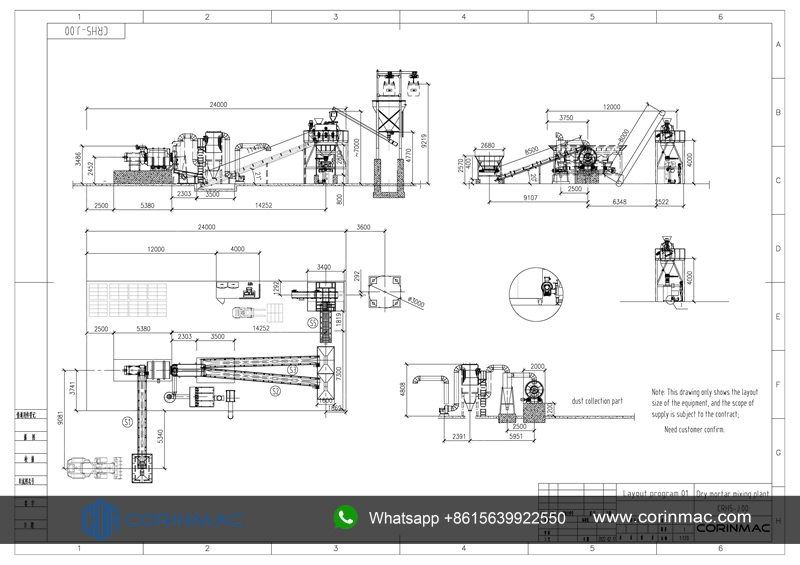

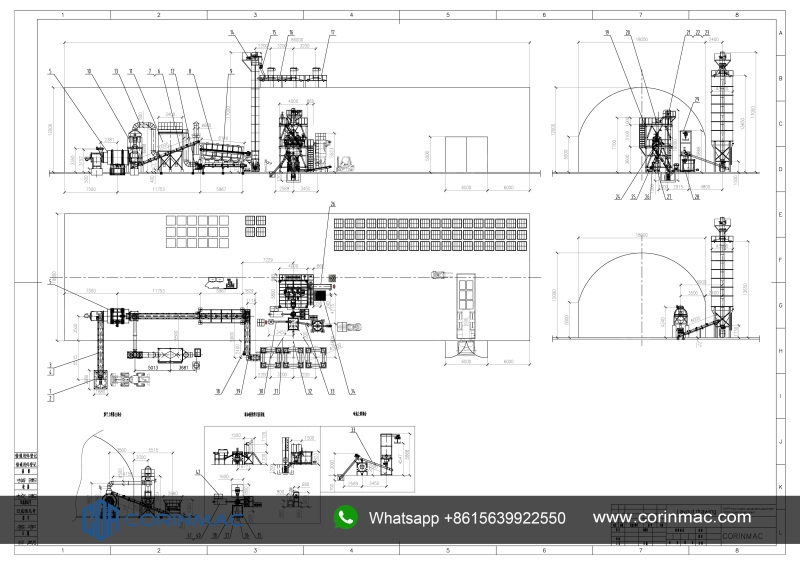

Ügyfelünk úttörő a 3D betonhabarcs-nyomtatási iparban.Több hónapos kommunikáció után a végleges, megerősített terv a következő.

Szárítás és rostálás után az adalékanyag a képlet szerinti mérésre az adagoló garatba kerül, majd a nagy dőlésszögű szalagos szállítószalagon keresztül a keverőbe.A tonnazsákos cementet a tonnazsákos ürítőn keresztül ürítik ki, és a csigás szállítószalagon keresztül a keverő feletti cementmérlegelő garatba kerül, majd a keverőbe.Adalékanyagként a keverő tetején található speciális adalékanyag adagoló garat berendezésen keresztül jut be a keverőbe.Ezen a gyártósoron egy 2 m³-es egytengelyes eke-keverőt használtunk, amely alkalmas nagyszemcsés adalékanyagok keverésére, végül a kész habarcs kétféle módon, nyitott fedőzsákos és szelepes zacskók csomagolására alkalmas.

-

Testreszabott szárazhabarcs gyártósor alacsony műhelyekben

Idő:2021. november 20.

Elhelyezkedés:Aktau, Kazahsztán.

A felszerelés helyzete:1 készlet 5TPH homokszárító sor + 2 lapos 5TPH habarcs gyártósor.

Egy 2020-ban közzétett jelentés szerint a kazahsztáni szárazhabarcs-piac várhatóan körülbelül 9%-os CAGR-rel fog növekedni a 2020-2025 közötti időszakban.A növekedés hátterében a növekvő építőipari tevékenység áll az országban, amelyet kormányzati kezdeményezések infrastruktúra-fejlesztési program támogat.

Termékek tekintetében a cementbázisú habarcs a domináns szegmens a száraz vegyes habarcsok piacán, és a piaci részesedés túlnyomó részét teszi ki.A polimerrel módosított habarcsok és más típusú habarcsok azonban várhatóan népszerűbbek lesznek a következő években olyan kiváló tulajdonságaik miatt, mint a jobb tapadás és rugalmasság.

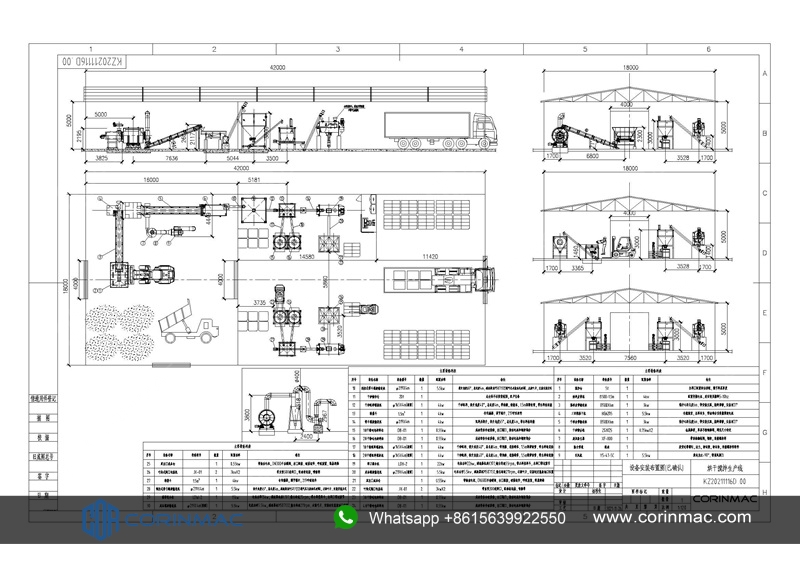

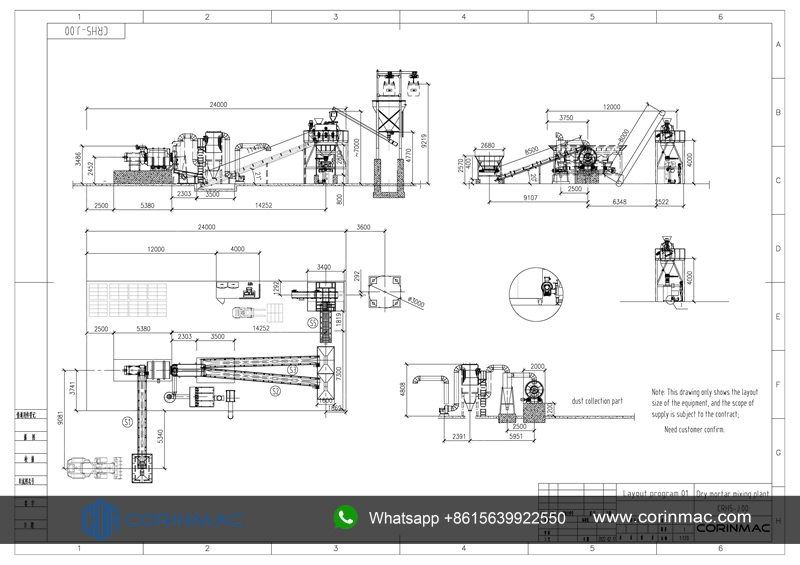

Különböző vevőknek különböző területű és magasságú műhelyei vannak, így még azonos gyártási követelmények mellett is a különböző felhasználói helyszíni feltételeknek megfelelően rendezzük el a berendezéseket.

A felhasználó gyárépületének területe 750 ㎡, magassága pedig 5 méter.Bár a munkaház magassága korlátozott, nagyon alkalmas laposhabarcs gyártósorunk elrendezésére.A következő a gyártósor végleges elrendezési diagramja, amelyet megerősítettünk.

A következő a gyártósor elkészült és gyártásba helyezése

Az alapanyag homokot szárítás és szitálás után a száraz homoktárolóban tárolják.A többi nyersanyag kirakodása a tonnazsákos ürítőn keresztül történik.Minden nyersanyag pontosan át van fürdetve a mérő- és adagolórendszeren, majd a nagy hatékonyságú keverőbe kerül a szállítócsigáson keresztül a keveréshez, végül a szállítócsigáson áthaladva belép a késztermék-hoppeba a végső zsákoláshoz és csomagoláshoz.A teljes gyártósort PLC vezérlőszekrény vezérli az automatikus működés megvalósítása érdekében.

Az egész gyártósor egyszerű és hatékony, zökkenőmentesen működik.

-

Tűzálló anyagok gyártósora Malajziába

Projekt helyszíne:Malaysia.

Építési idő:2021. november.

Projekt neve:Szeptember 4-én szállítjuk ezt a növényt Malajziába.Ez egy tűzálló anyagokat gyártó üzem, a normál szárazhabarcshoz képest a tűzálló anyagoknak több fajta nyersanyagra van szükségük a keveréshez.Az általunk tervezett és elkészített teljes adagolási rendszert ügyfelünk nagyra értékelte.A keverő részhez bolygókerekes keverőt alkalmaz, amely szabványos keverő a tűzálló anyagok gyártásához.Ha relatív igényei vannak, forduljon hozzánk bizalommal!

-

Száraz habarcskeverő üzem homokszárítással Shimkentbe

Projekt helyszíne:Simkent, Kzazkhsztán.

Építési idő:2020. jan.

Projekt neve:1 készlet 10 tph homokszárító üzem + 1 készlet JW2 10 tph szárazhabarcskeverő üzem.Január 6-án az összes berendezést konténerekbe rakták a gyárban.A szárítóberendezés fő berendezése a CRH6210 háromhengeres rotációs szárító, homokszárító üzem nedves homokgarattal, szállítószalagokkal, rotációs szárítóval és vibrációs szitával.Az átszitált száraz homokot 100T-s silókban tárolják és szárazhabarcsgyártáshoz használják fel.A keverő a JW2 kéttengelyes lapátos keverő, amit súlytalan keverőnek is neveztünk.Ez egy komplett, tipikus szárazhabarcs gyártósor, kérésre különböző habarcsok is készíthetők.

Ügyfélértékelés

"Nagyon köszönöm a CORINMAC segítségét a folyamat során, ami lehetővé tette a gyártósorunk gyors gyártásba helyezését. Nagyon örülök annak is, hogy ennek az együttműködésnek köszönhetően barátságunk alakult ki a CORINMAC-cal. Reméljük, mindannyian egyre jobbak leszünk, akárcsak a CORINMAC cég neve, win-win együttműködés!"

---ZAFAL

-

Gipszhabarcs és cementhabarcs gyártósor

Projekt helyszíne:Taskent-Üzbegisztán.

Építési idő:2019. július.

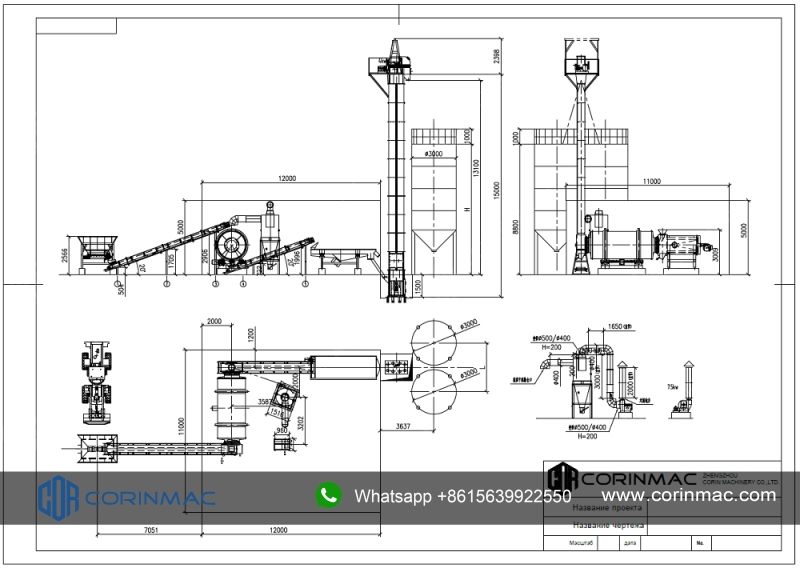

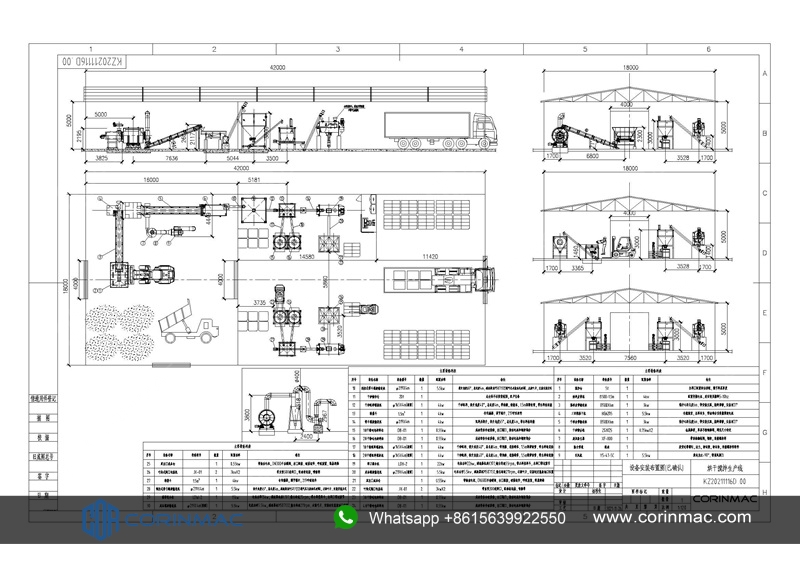

Projekt neve:2 készlet 10TPH szárazhabarcs gyártósor (1 készlet gipszhabarcs gyártósor + 1 készlet cementhabarcs gyártósor).

Az elmúlt években Üzbegisztánban nagy kereslet mutatkozott az építőanyagok iránt, különösen Taskent, Üzbegisztán fővárosa számos városi infrastruktúra és építési projektet épít, köztük két metróvonalat, valamint nagy kereskedelmi központokat és lakóközpontokat.Az üzbegisztáni statisztikai osztály statisztikái szerint az építőanyagok importértéke 2019 januárja és márciusa között elérte a 219 millió amerikai dollárt, ami teljes mértékben mutatja, hogy Üzbegisztánban az építőanyagok iránti kereslet növekszik.

Tudjuk, hogy az építőanyagok szerkezeti építőanyagokra és dekoratív építőanyagokra oszlanak, a dekoratív építőanyagok közé tartozik a márvány, csempe, bevonatok, festékek, fürdőszobai anyagok stb. Ezért a dekoratív építés területén a szárazon kevert habarcs iránti kereslet növekszik. is gyorsan emelkedik.Az a vevő, aki ezúttal együttműködött velünk, látta ezt a lehetőséget.Részletes vizsgálat és összehasonlítás után végül úgy döntöttek, hogy együttműködnek velünk, a CORINMAC-cal, hogy 2 db 10TPH szárazhabarcs gyártósort építsenek Taskentben, amelyek közül az egyik a gipszhabarcs gyártósor, a másik pedig a cementhabarcs gyártósor.

Cégünk üzleti képviselői részletesen ismerik a megrendelő igényeit és aktuális helyzetét, részletes programtervezést végeztek.

Ennek a gyártósornak kompakt szerkezete van.Az üzem magasságának megfelelően 3 db négyzet alakú homokgaratot állítottunk fel 3 különböző szemcseméretű homok (0-0,15 mm, 0,15-0,63 mm, 0,63-1,2 mm) tárolására, és függőleges szerkezetet alkalmazunk.A keverési folyamat után a kész habarcsot közvetlenül a késztermék-garatba csepegtetik a gravitáció hatására, hogy megcsomagolják.A termelés hatékonysága jelentősen javul.Cégünk mérnököket küldött a munkaterületre, hogy teljes körű és teljes folyamatra kiterjedő segítséget és útmutatást nyújtsanak az előzetes helyszíni elrendezéstől a gyártósor összeszereléséig, üzembe helyezéséig és próbaüzeméig, ezzel megtakarítva a megrendelő idejét, lehetővé téve a projekt kivitelezését. gyorsan termelésbe állítani és értéket teremteni.

Ügyfélértékelés

"Nagyon köszönöm a CORINMAC segítségét a folyamat során, ami lehetővé tette a gyártósorunk gyors gyártásba helyezését. Nagyon örülök annak is, hogy ennek az együttműködésnek köszönhetően barátságunk alakult ki a CORINMAC-cal. Reméljük, mindannyian egyre jobbak leszünk, akárcsak a CORINMAC cég neve, win-win együttműködés!"

---ZAFAL